Large Eddy Simulation of Turbulent Reacting Flows

(Current research by by Matthias Ihme, Ed Knudsen and Dirk Veenema)

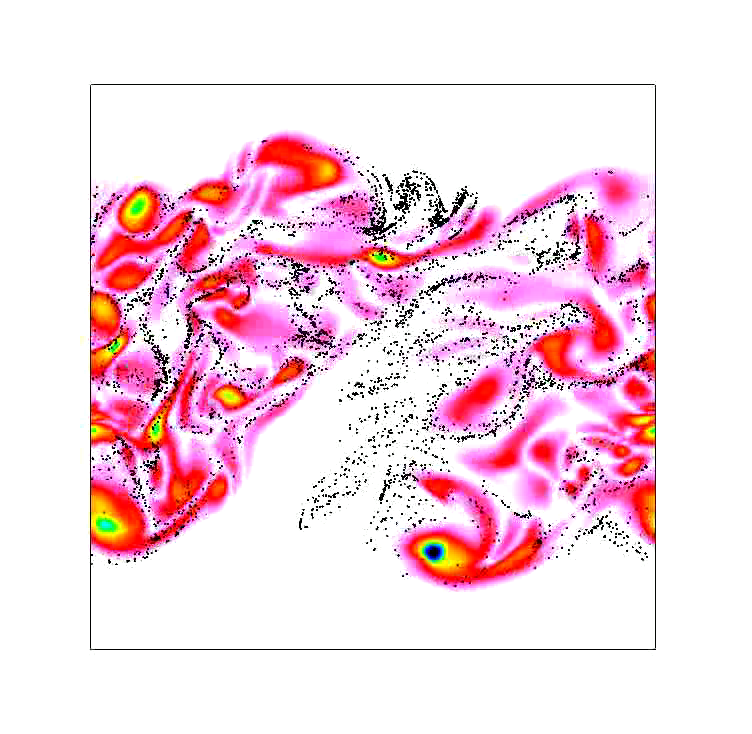

Large-eddy simulation (LES) is an approach to solving turbulent flows in which the larger scales of turbulent motion are exactly resolved while the smaller scales are modeled. This approach, as compared to the traditional Reynolds Averaged Navier-Stokes (RANS) method in which all turbulent scales are modeled, leads to significantly improved results in many real world flows. Such improvement is due to the resolution of the large turbulent scales. The chemical reactions that control combustion, however, occur on the smallest scales of the flow and hence can almost never be fully resolved. As such, modeling approaches are needed in order to accurately predict the chemical behavior of reacting flows. Furthermore, different modeling approaches are required in premixed and non-premixed combustion...

(Current research by Olivier Desjardins)

Practical combustors also involve multiphase systems where the fuel is injected as a liquid jet that breaks up to form secondary droplets. These droplets then evaporate to form the gas-phase fuel that passes through the combustion zone. In addition, fuel rich high temperature regions can cause soot formation that leads to solid particle evolution inside a combustor. Such multiphase multi-physics phenomena can be captured by a modular modeling approach. Different physical regimes of the combustor, namely primary breakup, secondary atomization, combustion, soot formation can be studied using independent target cases.

Combustion Models for Modern Reciprocating Engines

(Current research by David Cook and Prahallad Iyengar)

We are interested in developing combustion and ignition models for a range of internal combustion engines. In the past our research efforts were mostly focused on diesel engines, as they have been shown to have higher efficiencies than gasoline engines. However, in recent years we have focused on developing models for Homogeneous-Charge Compression Ignition (HCCI) engines because they have been shown to have higher thermal efficiencies and lower NOx and soot emissions than Spark Ignition (SI) engines. While a promising technology, HCCI engines experience high levels of carbon monoxide (CO) and unburnt hydrocarbon (UHC) emissions. Improving CO and UHC emissions in HCCI engines requires a fundamental understanding of the interactions of chemical kinetics, fuel/air/EGR mixing, heat loss, and transport between near wall and cylinder core regions. Therefore, we have developed a ignition and combustion model based on detailed chemical kinetics for HCCI engines...

Experimental Investigation and Multi-scale Modeling of Polymer Electrolyte Fuel Cells

(Current research by Venkat Viswanathan , Frank Wang, Seung Hyun Kim, and Steve Walch (consulting professor)

Research in this area focusses on the development of a multi-scale model describing the electrochemistry in proton exchange membrane fuel cells (PEMFCs). Chemical and electrochemical reactions in PEMFCs occur on nano-size platinum particles. The multi-scale model is based on dynamic Monte Carlo (DMC) simulations of the chemistry on the surface of these particles. This allows considerations of specific chemical effects such as the influence of adatom interactions and active sites. The transition probabilities required for the DMC simulations are taken from literature data or determined from quantum simulations. To ultimately validate the simulations, experiments are performed under well-controlled conditions...

Development, Analysis, and Systematic Reduction of Chemical Mechanisms for Surrogate Fuels

(Current research by Perrine Pepiot)

Numerical simulations of practical combustion systems, such as furnaces, pool fires and even engines, often lack an adequate description of the involved chemistry. The reason is, most of all, that real fuels are composed of many single components, involving, for instance, aliphatic, aromatic, and alkylated aromatic components, but also cyclo-parrafins and possibly oxygenated components. For some of those components, detailed chemical kinetic mechanisms are already available. However, these mechanisms tyically consist of thousands of reactions and as many as one thousand chemical species...

Modeling of Soot Formation in Engines

(Current research by Guillaume Blanquart)

Pollutant formation has become a great concern because of public health and environmental consequences. In the near future, additional regulations will limit soot emission levels and require knowledge of the soot particle size distribution. The present work intends to develop an accurate model to describe formation of soot particles, which can be applied to technical devices such as gas turbine engines. The model involves detailed chemistry and a comprehensive description of soot particle dynamics and chemistry and describes the interactions with the turbulent flow. The particles are formed from aromatic gas phase species and grow by chemical reactions and condensation of molecules on the surface. Oxidation extracts mass from soot particles back into the gas phase...

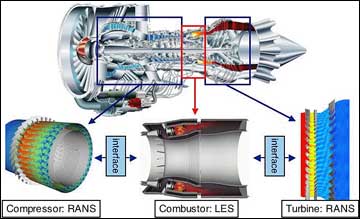

The mission of the LES-RANS integration group is to develop the infrastructures to perform multi-code simulations and to demonstrate large-scale computations on the ASC computing systems. The two CITS flow solvers, TFLO and CDP, are combined for an aero-thermal flow simulation of an entire aero-engine gas turbine. TFLO is based on the Reynolds-Averaged Navier-Stokes equations and is used for the simulation of the flow through the combustor and the turbine. CDP is a Large Eddy Simulation tool and is employed for predicting the reacting multiphase flow in the combustor chamber...