Development of Electroosmotic Pumps for Electronics Cooling Applications

Motivation

Electroosmotic (EO) pumps have no moving parts and offer distinct advantages over other micropumps, including high pressure capacity (on the order of a few atmospheres) and/or large flow rate (greater than 33 ml/min). This performance makes them suitable for microelectronic cooling applications of devices with order 100 W heat loads. Sintered glass electroosmotic pumps have been fabricated that provide maximum flow rates and pressure capacities exceeding 33 ml/min and 1.3 atm, respectively, at 100 V, with porous sintered glass cylinder (a frit) with 40 mm in diameter and 1 mm thick.

Project Description

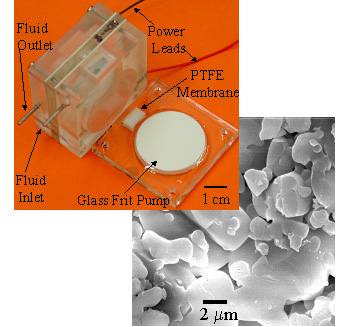

The sintered glass electroosmotic pumps studied here consist of a porous glass disk, a plastic casing, and fluidic tubing. Figure 1 shows an image of the pump components together with a scanning electron micrograph of the porous glass frit structure. The sub-micron pores in this structure provide the high surface area to volume ratio required to achieve both high flow rate and relatively high pressure generation.

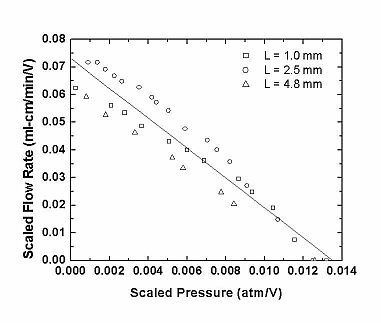

Figure 2 shows the scaled flow rate vs. the scaled pressure of the small-pore frit with pore radius 0.55 mm and thicknesses of 1.0 mm, 2.5 mm, and 4.8 mm. The flow rate is linearly related to the backpressure for a fixed voltage, as the model predicts. For a given applied potential, flow rate is inversely proportional to frit thickness and pressure remains constant. An important consideration for designers of large flow rate EO pumps is the flow rate and pressure achieved by a design for a given applied voltage. As discussed in the papers listed below, the use of a relatively dilute (< 1 mM) buffered working solution drastically increases pressure and flow rate capacities over that achieved with deionized water (DI) with an acceptable increase in thermodynamic efficiency.

References

Motivation

Electroosmotic (EO) pumps have no moving parts and offer distinct advantages over other micropumps, including high pressure capacity (on the order of a few atmospheres) and/or large flow rate (greater than 33 ml/min). This performance makes them suitable for microelectronic cooling applications of devices with order 100 W heat loads. Sintered glass electroosmotic pumps have been fabricated that provide maximum flow rates and pressure capacities exceeding 33 ml/min and 1.3 atm, respectively, at 100 V, with porous sintered glass cylinder (a frit) with 40 mm in diameter and 1 mm thick.

Project Description

The sintered glass electroosmotic pumps studied here consist of a porous glass disk, a plastic casing, and fluidic tubing. Figure 1 shows an image of the pump components together with a scanning electron micrograph of the porous glass frit structure. The sub-micron pores in this structure provide the high surface area to volume ratio required to achieve both high flow rate and relatively high pressure generation.

Figure 1. An image of the pump components showing stainless steel flow connections and device power leads.

Figure 2 shows the scaled flow rate vs. the scaled pressure of the small-pore frit with pore radius 0.55 mm and thicknesses of 1.0 mm, 2.5 mm, and 4.8 mm. The flow rate is linearly related to the backpressure for a fixed voltage, as the model predicts. For a given applied potential, flow rate is inversely proportional to frit thickness and pressure remains constant. An important consideration for designers of large flow rate EO pumps is the flow rate and pressure achieved by a design for a given applied voltage. As discussed in the papers listed below, the use of a relatively dilute (< 1 mM) buffered working solution drastically increases pressure and flow rate capacities over that achieved with deionized water (DI) with an acceptable increase in thermodynamic efficiency.

Figure 2. Pressure load characterization shown as scaled flow rate versus pressure per volt for three pumps of the batch with pore radius 0.55 mm and three thicknesses. Working fluid is 1 mM (sodium ion concentration) Borate buffer (pH = 9.2, s = 77 ms/cm). These pumps were able to deliver a maximum flow rate excess of 7e-2 ml-cm/min/V and a maximum pressure of 1.3e-2 atm/V.

References

- 1.) Jiang, L., Mikkelsen, J.C.,

Koo, J-M, Zhang, L., Huber, D., Yao, S., Bari, A., Zhou, P.,

Santiago, J.G., Kenny, T., & Goodson, K.E., 2002, “Transient

and sub-atmospheric performance of a closed-loop electroosmotic

microchannel cooling system,” THERMES 2002 Workshop, Santa Fe, New

Mexico, USA.

- 2.) Zeng, S., Chen, C., Mikkelsen,

J.C., and Santiago, J.G., 2001, “Fabrication and characterization

of electroosmotic micropumps,” Sensors and Actuators B, 79 (#2-3),

107-114.

- 3.) Zeng, S., Chen, C., Santiago,

J.G., Chen, J., Zare, R.N., Tripp, J.A., Svec, F., and Fr?chet.

J., 2001, “Electroosmotic Flow Pumps with Polymer Frits,” Sensors

and Actuators B, 82(#2-3), 209-212.

- 4.) Yao, S., Huber, D., Mikkelsen,

J.C., and Santiago, J. G., 2001, “A large flowrate electroosmotic

pump with micron pores,” Proceedings of the International

Mechanical Engineering Congress and Exposition, Sixth

Microfluidics Symposium, New York, New York.

- 5.) Yao, S., Zeng, S., and Santiago, J. G., 2002, “Temporal response of porous glass electroosmotic pumps”, Proceedings of 2002 ASME International Mechanical Engineering Congress and Exposition, New Orleans, Louisiana.

- 6.) Yao, S., and Santiago, J. G., 2003, “Porous Glass Electroosmotic Pumps: Theory,” Journal of Colloid Interface Science, 268, 133-142.

- 7.) Yao, S., Hertzog, D. E., Zeng, S., Mikkelsen, J. C., and Santiago, J. G., 2003, “Porous Glass Electroosmotic Pumps: Design and Experiments,” Journal of Colloid Interface Science, 268, 143-153.