1. Optical Ceramics: Definition & Advantage

Polycrystalline materials, are solids that are comprised of a collection of crystallites (grains), separated from one another by areas of relative disorder known as grain boundaries. The assemblage of grains of various shapes and sizes, together with the potential presence of porosity and secondary phases, constitute the ceramic microstructure. Many of the physical properties of ceramics are microstructure dependent, as are its optical properties. In order to collect the maximum light output, the emission and absorption spectra of a scintillator material have to be well separated. This means that the scintillator material has to be transparent at its emission wavelength. Optical ceramics are transparent polycrystalline materials that can be used as an alternative to single crystals scintillators. These are produced by ceramic fabrication methods. The advantage of optical ceramics is the possibility of production of reasonably priced and large sized materials for large area detection. Fabrication techniques are also much less time consuming than that of single crystals.

Scintillator Optical Ceramics: The State of the Art

The first transparent scintillator ceramics were developed in the early 80ís in order to meet a need in the medical imaging domain. A review on the manufacturing, characterization, and performance of (Y,Gd)2O3:Eu and Gd3Ga5O12:Cr,Ce ceramics was reported by Greskovich for computed tomography applications. In 1997, Ce doped YAG scintillator ceramic have been synthesized and their scintillation characteristics were compared to those of single crystals. In 2002, Lu2O3:Eu transparent ceramics have been obtained and their performance was compared to CsI:Tl single crystals.

However, it should be noted that the previously mentioned materials have cubic structure. For non cubic polycrystalline materials, light is scattered as a result of the discontinuity in the refraction index between the randomly oriented grains. This leads to translucency. So far, transparency was not a critical criterion for applications that do not require large thickness of scintillator material. These could still benefit from translucent ceramic scintillators. Such is the case for Gd2O2S:Pr, widely used in computed tomography and where Greskovich achieved only translucency because of its hexagonal structure.

At the present time, most of the modern and efficient scintillators are non cubic materials. Boatner et al. reported in 2007 on Ce doped LSO (monoclinic structure) and LaBr33. Although this work has reported good results, the fabrication process of a totally transparent ceramic for non cubic materials is not very well understood. For this reason it is of a primary interest to identify the mechanisms by which the light is scattered in this type of materials and how to eventually reach transparency.

1. Origin of light scattering in polycrystalline materials

Sources of light scattering are numerous in polycrystalline materials. They are mainly related to refractive index discontinuities in (1) the microstructure due to the presence of composition inhomogeinities and pores, and (2) at the interface of birefringent crystallites randomly oriented in non cubic materials.

1.1. Refractive index discontinuities in the microstructure

Polycrystalline materials present a large number of discontinuities in their bulk due to their microstructure (fig. 1). These include randomly oriented grains, grain-boundaries and sometimes residual pores and secondary phases. The main challenge in the fabrication of transparent ceramic is to get rid of all the porosity and avoid the formation of secondary phases. In addition, grain boundaries must be kept as thin as possible and the grain size controlled.

Figure 1: Scattering of light in polycrystalline ceramics due to microstructural imperfections.

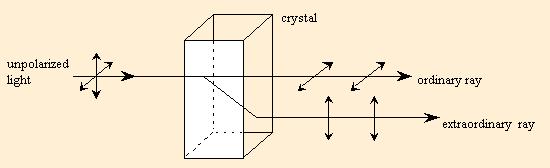

1.2. Refractive index discontinuities due to birefringence

Materials with cubic structure are optically isotropic, while non cubic materials are optically anisotropic (i.e birefringent). Birefringence is the decomposition and unpolarized ray into two rays, extraordinary (polarization parallel to the anisotropy axis) and ordinary ray (polarization perpendicular to the anisotropy axis) when it passes through an anisotropic material (fig. 2). If the material is unixial (single axis of anisotropy), the magnitude of birefringence is defined as ?n= ne-no, where ne and no are the refractive indices of the extraordinary and ordinary ray respectively.

Figure 2: Decomposition of unpolarized light to ordinary and extraordinary ray in a birefringent material.

When the material is biaxial, the refractive indices are different along the three space directions (x, y, z) and we obtain nx, ny and nz. In polycrystalline materials, birefringence leads to a discontinuity of the refractive index at the grain boundaries because the crystallographic orientation of the neighboring grains is not the same. The more the difference of refractive index ?n between two grains is high, the less transparent the material. Thus, due to birefringence effect light is scattered in the material and leads to either translucency or total opacity.

2. Optical Ceramic Fabrication

In order to control the optical properties of a polycrystalline material, we need to control the microstructure and eliminate the birefringence effect during the fabrication process. As mentioned above, discontinuities in the microstructure can be avoided by eliminating all the pores and controlling the grain size. This can be achieved during sintering of the ceramic.

2.1. Densification during Sintering

Sintering is the process by which a powder compact is transformed to a strong, dense ceramic body upon heating. It can occur in the presence of a liquid phase which leads to liquid phase sintering. In the absence of a liquid phase, the process is referred to as solid state sintering.The macroscopic driving force operative during solid state sintering is the reduction of the excess interfacial. This can happen by (i) reduction of the total surface area by an increase in the average size of the particles which leads to coarsening and/or (ii) the elimination of solid/vapor interfaces and the creation of grain boundary area, followed by grain growth, which leads to densification. If the atomic processes that lead to densification dominate, the pores get smaller and disappear with time and the compact shrinks. But if the atomic processes that lead to coarsening are faster, both pores and grains get larger with time. Thus, full densification is obtained when the atomic processes associated to coarsening are suppressed, while those associated with densification are enhanced.

2.2. Texture

Suppressing the birefringence effect at the randomly oriented grains demands to reorient the grains so that the difference of refractive index is minimal in the direction normal to the lattice preferred orientation. This grain-orientation is commonly referred to as texture. Texture influences all macroscopic physical properties of a material which are crystallographically anisotropic. It may be induced in the solid-state through plastic deformation or grain-recrystallization.

There are mainly two different techniques to induce texture in ceramics. It can be formed in the green state by an application of an electromagnetic field in the case where the material has a magnetic susceptibility. The second technique concerns the application of a gradient field. This can be an electric field or a pressure gradient. To achieve good densification with texture, hot pressing is the most suitable technique.

Adapted from a report by Atlal Laouar.

>>Return to Background & Fundamentals page<<