Contents

- The evolution of C-VIC into the commercial product Lingraphica shows the mix of hard work and good luck that

makes tech transfer happen.

- The fingerspelling hand evolves in technology to

provide simpler operation and greater reliability as it moves on to clinical

evaluation.

- The Vocational Training Facility casts DeVAR, the

desktop vocational assistant robot, in a supporting role as it enables severely

disabled students learn useful desktop publishing skills through interactive

videodisc and hands-on experience.

- SIMM, the software for interactive musculoskeletal

modeling, takes flight as its two developers leave to form a company to enhance

SIMM and develop new biomechanics software.

- Tech Tranfer Briefs

A journey from concept to

commercialization - Lingraphica

Alvin H. Sacks and Richard Steele

Lingraphica is an assistive and therapeutic device for persons with aphasia,

a disorder in which the parts of the brain responsible for sending, receiving,

and interpreting language has been severely damaged, usually by some type of

brain trauma (e.g., stroke). At present there are nearly 1 million aphasic

individuals in the US, with 100,000 new cases annually. The story of how this

therapeutic device came into being is a fine tale of technology transfer:

In early 1984, a research scientist and linguist from this Center, Richard

Steele, PhD, met with a team of investigators from the Boston Aphasia Research

Center to discuss opportunities for collaborative R&D. The Boston team

described work done in the early 70's on VIC, a low-tech visual communication

system for those afflicted with global aphasia. They presented a method of

communication which used decks of cards with pictures or symbols that could be

manipulated by the patient to produce meaningful, if elementary, communication.

It was evident to Steele and the other researchers that the method was both

cumbersome and limited and that it could be vastly improved and expanded by

intelligent use of the emerging personal computer technology that employed high

resolution graphic displays. He began formulating a project to develop a

computerized visual communication system for aphasics, dubbed C-VIC, which

would require only moving the mouse with one hand, since those affected by

stroke often also lose neurologic function on one side of their body. C-VIC

would simply involve manipulating a screen representation of the paper cards

which had been used in the original VIC system. These stacks of on-screen

"cards" contained the symbols and pictures needed for essential

communication.

With the concentrated involvement of Michael Weinrich, MD, then Chief of

Neurology at the Palo Alto VA Medical Center, as well as speech therapists and

a programmer, Steele proceeded, with VA funding, to develop, refine and test

the system on aphasic patients at several medical centers.

Patent sought for the basic technology

By 1987 the C-VIC system had demonstrated its functional value, and the

inventors filed a Disclosure of Invention with the General Counsel for their

agency, the Department of Veterans Affairs (DVA) in Washington, DC, as required

of all federal employees involved in technology development. In consideration

of the circumstances and the interests of the DVA, General Counsel informed the

researchers that the US Government was turning over all patent rights to them,

with the usual condition that the Government retain a royalty-free, paid-up

license to make and use the invention for government purposes.

In 1989, a license was negotiated between the inventors and an

entrepreneurial group in San Jose, CA for further development and

commercialization of the C-VIC technology. The following year, this group

formed a new start-up company, Tolfa, and sublicensed the C-VIC technology in

order to develop and market it as a commercial product. Shortly thereafter,

Tolfa hired the Principal Investigator and primary inventor, Richard Steele.

Even though this means of technology transfer may draw talent away from the

originating federal laboratory, it makes extremely good sense for the users of

the technology, particularly if further improvement and secondary products are

likely.

In the remarkably short time of just under one year (on February 7, 1991),

the commercial product - much improved, and renamed Lingraphica - appeared on

the market in the form of a specially labeled, dedicated Apple Macintosh

Portable computer, with Tolfa as a Value-Added Reseller, by agreement with

Apple Computer. The commercial product includes such features as voice and

animation. It also automatically records usage data for use by therapists. The

developer had applied for FDA approval of the device as a piece of Class 2

medical equipment, and the approval was received in December 1990. It is the

first equipment of its type for rehabilitation of persons with aphasia. In the

latter half of 1992, DVA sites in Phoenix, AZ, and Nashville, TN began a formal

evaluation of Lingraphica as a prosthetic device for speech-language

communication.

A patent application on the underlying technology was filed in 1990 with the

U.S. Patent and Trademark Office, and the patent was issued on December 8,

1992. In January 1993, the DVA formally approved the device for inclusion in

its list of prescribable prosthetic appliances for eligible veterans.

Lessons from the journey

Lingraphica is an excellent example of a successful rehabilitation product

invented in a DVA federal laboratory and commercialized by a private company.

Yet even in this most successful of cases, one should note the long time span

from conception to market - in this case nearly seven years!

Lessons from the journey

Lingraphica is an excellent example of a successful rehabilitation product

invented in a DVA federal laboratory and commercialized by a private company.

Yet even in this most successful of cases, one should note the long time span

from conception to market - in this case nearly seven years!

We learned several lessons from this experience, including the following:

- Tech transfer does not come about quickly, even in the best of

circumstances.

- The time from transferring a working laboratory prototype to seeing a

product on the market can be reasonably short if the company is small,

adequately funded, and smart and thorough in its approach.

- Hiring the inventor or developer is often critical to success.

- Even though the federal laboratory loses a valuable inventor or

investigator, there may be no more effective means of fulfilling its mission to

transfer its technology.

- The movement of promising technology to industry offers the private sector

valuable knowledge, expertise, and R&D which they might otherwise not be

able to afford.

Science, meet serendipity

Finally, we note the circumstances that brought about this licensing

arrangement. One day, shortly after the government had released the rights to

C-VIC to its inventors, an entrepreneur, later to be the president and CEO of

Tolfa, walked into the RR&D Center looking for potential products to

commercialize for the rehabilitation market. He selected C-VIC as the most

promising. He came to visit our Center at just that time because (1) he was in

the process of raising venture capital to start a new company, (2) he knew our

Director as a colleague, and (3) his wife is a physical therapist, familiar

with rehabilitation techniques. The product that grew out of this visit

illustrates one final lesson: as with many other endeavors in life, successful

tech transfer is the fruit of good preparation meeting the unexpected

opportunity of circumstance.

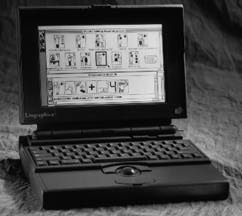

Early versions of C-VIC ran on a Macintosh Plus computer, shown here in use

by a person with aphasia.

For persons with aphasia, Lingraphica provides novel, important, and useful

support for improving communication in real-life situations. It does this by

providing access to an extensive database of more than 2000 'word-concepts',

each of which can display its meaning in graphics (e.g., icons, animated when

appropriate), text (printed word), and voice (digitized speech).

The system additionally allows such 'lingraphic icons' to be assembled into

larger constructions, to communicate sentence-like meanings (e.g., 'doctor

writes prescription'). Users may compose messages by pointing with the mouse

and dragging icons to 'storyboards', there, Lingraphica automatically

translates icon sequences into text and spoken words.

"Patient Screen," a

sample display screen showing the vocabulary window ("Picture

Gallery") above and the message construction window

("Storyboard") below.

"Patient Screen," a

sample display screen showing the vocabulary window ("Picture

Gallery") above and the message construction window

("Storyboard") below.

An able communicator can respond by typing text at the keyboard (with

automatic picture look-up). Storyboard communications may be stored for later

retrieval and reuse; they may also be written to diskette for transfer to, and

use on, a Lingraphica system elsewhere.

Lingraphica is a registered trademark of Tolfa Corporation.

A third generation fingerspelling

hand

David L. Jaffe

The first issue of OnCenter reported the development of Dexter, a computer

controlled mechanical hand that enables a deaf-blind individual to receive

tactile messages during person-to-person communication sessions - substituting

for a human interpreter - and to gain access to electronic information.

A smaller, lighter, and more intelligible version of Dexter has been

constructed under contract from Gallaudet University, with funding from NIDRR.

It, like its predecessor, translates keyboard key-presses or electronic

representations of letters into movements of the fingers of the mechanical

hand. In a technique called fingerspelling, these movements are felt by the

hand of a deaf-blind user and interpreted according to the American One-Hand

Manual Alphabet as letters comprising a message. With a fingerspelling hand, a

deaf-blind individual need not rely on a human interpreter for all

communication.

More reliable, better control

Significant improvements in the mechanical, computer, and software systems are

embodied in this new device. Mechanically, each hand motion is driven by a

servo motor as in Dexter. Cables are wound around the motors' pulleys, routed

up each finger, and attached to their tips. The fingers themselves are

constructed of Delrin segments attached to each other by a strip of carbon

fiber, replacing the torsion springs used in Dexter. The carbon fiber provides

the flexible hinge for finger flex and the restoring force necessary to extend

the finger.

The system's computer hardware consists of an 8 bit microcontroller module

and associated digital circuitry. This compact assembly unit is mounted behind

the servo motors under the hand. The computer software implements a new

fingerspelling algorithm that results in smooth transitions from one letter to

the next. Also, a finger-position editing utility makes it possible to optimize

the hand movements to increase intelligibility.

When using this system, a sighted person wishing to talk to a deaf-blind

individual interacts with the fingerspelling hand by using an Atari Portfolio

hand-held computer through a serial connection. In practice, any device that

produces serial data, including terminals, modems, computers, or modified

closed caption systems, could be used to control the hand.

In the fingerspelling mode, keypresses are entered on the Portfolio, and the

hand's software translates these keypresses into commands for the servo motors.

As the motor shafts rotate, they pull on the cables that are the

"tendons" of the fingers. It is by a coordinated series of motor

commands that keyboard input is transformed into choreographed motion

representing fingerspelling.

Clinical evaluation now in progress

Two fingerspelling hands have been constructed and will be placed in the homes

of several deaf-blind individuals for extended periods of clinical evaluation

through June, 1993. For successful commercialization, other tech transfer

issues need to be addressed beyond this evaluation. The market for

fingerspelling hands must be assessed, and a comprehensive plan for

manufacturer collaboration is needed to move this device out of the research

laboratory and into commercial availability.

In our experience, encounters with Dexter have been enthusiastic, positive,

and at times, highly emotional. The increased communication capability and

ability to "talk" directly with people other than interpreters are

powerful motivations for using a fingerspelling hand. It has the potential to

provide deaf-blind users with untiring personal communication at rates

approaching that of a human interpreter.

This fingerspelling hand uses flexible carbon fiber hinges to connect the

finger segments and a hand-held computer for input and control.

VTF moves students into the

community

Machiel Van der Loos & Joy Hammel

The Vocational Training Facility (VTF) is a VA Merit Review Development

Project. Its goal is to provide an integrated and accessible learning

environment for students with severe physical disabilities such as high-level

quadriplegia from spinal cord injuries. Using the VTF curriculum in Desktop

Publishing (DTP), a student is in command of a self-paced curriculum on a

customized, accessible workstation. In three months, each student develops the

skills for entry-level competence in DTP. In transferring knowledge to the

students the VTF seeks to transfer the students to profitable employment.

During its first 18 months, the VTF developed a Macintosh-based curriculum

in Desktop Publishing instruction using a multimedia approach. The VTF

developed training materials on videodisc, evaluated and integrated

commercially available instructional materials, developed exercises and tests,

and wrote a HyperCard environment to allow a student to use all the different

learning tools. In addition, at the start of the three-month training sequence,

a workstation is tailored to each student's abilities. The list of possible

devices includes trackballs, keyboard holders, mouthsticks, voice-recognition

units, environmental controls, and DeVAR, the desktop vocational assistant

robot mounted over the workstation. The equipment assures that the students are

all capable of taking care of their daily living needs, even without the

assistance of an attendant, regardless of their level of ability.

The VTF is starting its third session this month. Our past two groups of

three students have shown that the course is a success. Five of the six have

gone on to 3-month internships in local companies and organizations to gain

real-world skills before hitting the job market. The one student who could not

complete the VTF course for medical reasons showed the value of the self-paced

approach to learning and is now continuing his DTP education at a local

college.

The VTF will continue until the end of 1993. By then, 15 to 18 students will

have been trained in DTP. This will be a very successful technology transfer in

and of itself. Beyond VTF, we see our curriculum as being appropriate for other

types of disabilities, as well as other learning forums such as community

colleges, and certainly for other vocational areas such as accounting, CAD, and

industrial training. We are very interested in pursuing the VTF concept with

industrial partners looking at individualizing their training methods and

making the materials accessible to students of all physical ability levels.

The DeVAR robotic assistant helps students learn Desktop Publishing skills

using a self-paced interactive-video curriculum.

Tech Transfer Briefs

Commercial partners sought for graphic Braille display Computer

access for the visually impaired person continues to challenge the ingenuity of

programmers and engineers. To date, computer interfaces for the blind have been

based on two techniques: text-to-speech and tactile sensing. Unfortunately,

speech output has several disadvantages, most notably that the text must be

presented in sequential order. Also, not all computer text can be easily or

meaningfully converted to speech. Tactile displays offer many potential

advantages but are currently limited by cost and complexity. An investigator at

this Center has recently completed a pilot project to develop an inexpensive,

quiet, reliable, energy-efficient Braille computer interface.

Biomedical Engineer Stefan Michalowski has designed and built a prototype

unit using a combination of mechanical and electrical components. The details

are not disclosed here in order to protect patentability, which is important

for potential manufacturers of a commercial device. The prototype has six pins

which are arranged in the Standard Braille pattern. It has been tested

extensively and has performed well. The current goal of the project is to

generate interest among commercial partners who would be willing to support the

transformation of this research prototype into a commercial product.

Joint project with Air Force on patient transport

Discussions are underway for a joint project in which this Center will work

with the US Air Force Armstrong Laboratory at Brooks AFB, San Antonio TX, to

improve stabilization of acute spinal injury patients during air evacuation and

hospitalization. This project will draw on experience here in technologies for

safe spinal stabilization during aeromedical and in-hospital transport of acute

spinal cord injury (SCI) patients. This expertise has been applied to the

design and evaluation of spinal stabilization devices used in local civilian

helicopter ambulances since 1985.

The Air Force is called upon to transport active duty service personnel from

the site of injury to regional DVA SCI Centers, and it is seeking methods of

safe spinal stabilization during short range transport and intercontinental

evacuation of patients with unstable spines. This project would apply both

motion analysis and accelerometry techniques to study the effectiveness of

various spinal stabilization devices. This is the first extensive collaboration

between the RR&D Center and the military. The DVA principal investigators

are Eric E. Sabelman, PhD and Inder Perkash, MD.

SIMM is now commercially

available

Peter Loan

As part of a project in surgery simulation at this Center, biomechanics

researchers in the Neuromuscular Systems Group developed the software package

SIMM (Software for Interactive Musculoskeletal Modeling). SIMM is a

graphics-based program designed to aid in the creation of mathematical models

of musculoskeletal structures which are then used to simulate the effects of

reconstructive surgical procedures.

To encourage the commercialization and continued development of the

software, the DVA released the patent rights for SIMM to the two inventors,

Scott Delp and Peter Loan. Delp and Loan subsequently formed a company,

MusculoGraphics, Inc., to market the software. Beyond its initial sales to

biomechanics researchers at university labs, MusculoGraphics is now expanding

its market to include several industrial sites.

The company has relocated to Evanston, IL, where it is continuing to enhance

SIMM as well as develop other biomechanics software. It recently hired two new

employees to help meet the growing demand for musculoskeletal modeling

software. For more information on SIMM, contact: Peter Loan, MusculoGraphics,

Inc. 1840 Oak Ave., Evanston, IL 60201.

For more information on any of these articles contact the author directly or

Al Sacks at 650/493-5000 ext 6-4475.