Silicon Based Electroosmotic Pumping for Direct Methanol Fuel Cells

Principal Investigators: J.G. Santiago, Cullen R. Buie

|

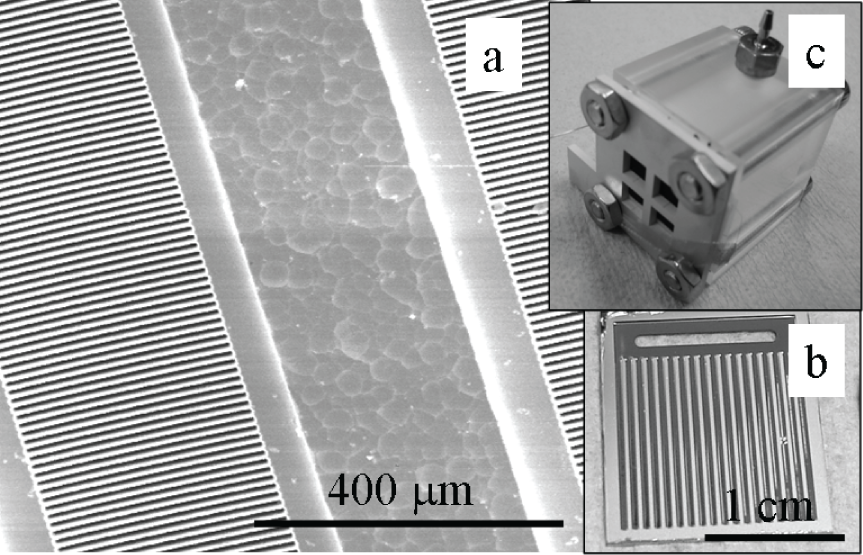

Figure 1. SEM (a), digital image (b) of the top view of our integrated EO pump/DMFC anode structure, and the full DMFC assembly (c). The SEM image is a top view into the flow channels showing the 5 mm wide EO pump slots etched into the bottom of the 400 mm wide anode flow channels. The pump slots deliver methanol perpendicular to the plane, out of the page, and into the anode channels. The anode channels (b) allow methanol to flow through the plane and react along the membrane electrode assembly (MEA). |

Fuel cells offer the potential of environmentally benign vehicle propulsion systems and high power density alternatives to batteries. Hydrogen is the most popular fuel but proton exchange membrane fuel cells (PEMFCs) also operate on various alcohols including ethanol and methanol. Direct methanol fuel cells (DMFCs) oxidize aqueous methanol solutions at the cell anode to yield electrical energy, waste heat, and carbon dioxide. Liquid methanol has roughly half the volumetric energy density of gasoline, making DMFCs attractive for applications with volume and weight constraints. We’ve developed direct methanol fuel cells (DMFCs) that utilize silicon based electroosmotic pumps for methanol delivery. Electroosmotic flow is the bulk motion of an electrolyte caused by coulombic interaction of external electric fields and the charges of an electric double layer (EDL). Electroosmotic (EO) pumps have no moving parts and can produce high flow rate per package volume. These properties make EO pumps highly suitable for fuel cell applications. In a recent MEMS 2006 conference paper1 we demonstrated the efficacy of supplying methanol to DMFCs using silicon EO pumps fabricated at the Stanford Nanofabrication Facility (SNF). An idealized schematic of our electroosmotic pumps assuming negligible pressure losses is shown in Figure 2.

|

Figure 2. Schematic of porous Si medium modeled as many microchannels in parallel. A single channel of the porous material is shown on the right. An electrical double layer (EDL) spontaneously forms on glass/electrolyte interfaces. Bulk motion in the channel is generated by a coupling of the applied electric field E and the net mobile charge in the EDL. |

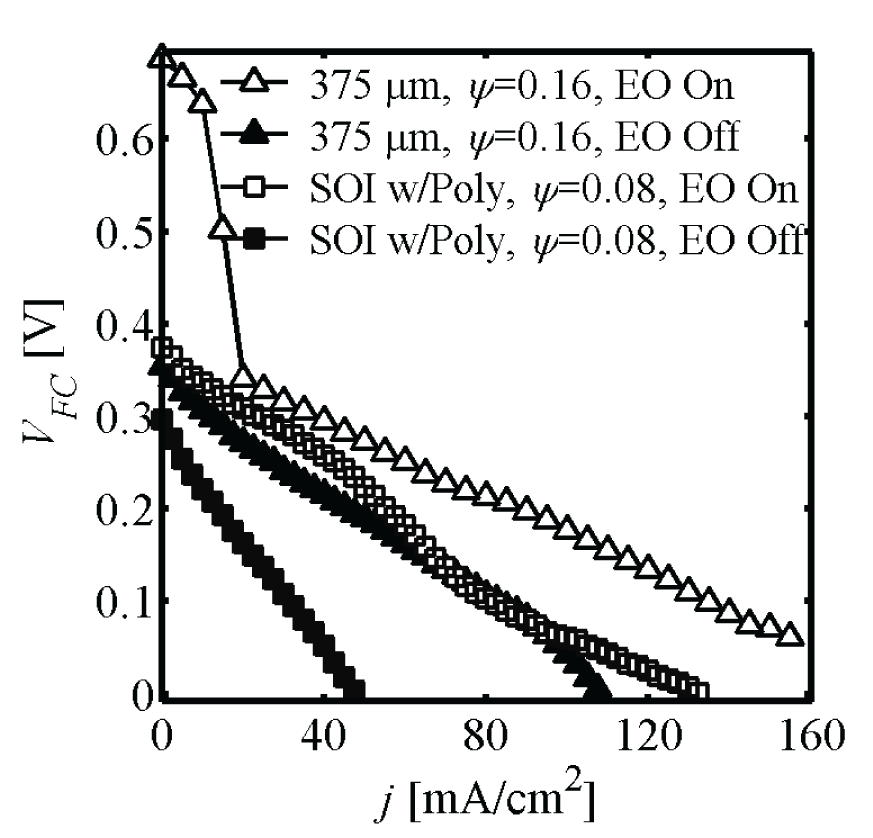

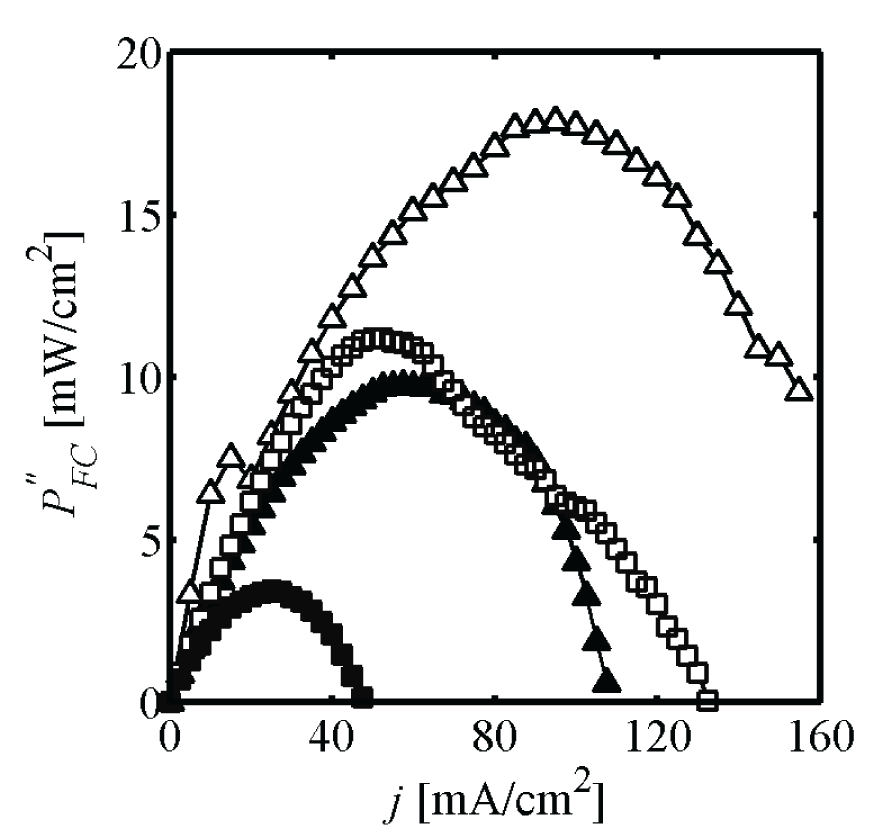

Polarization and power density data in Figure 3 show that activation of the EO pump significantly improves DMFC performance. In both cases, the EO pump activated tests (open symbols) result in higher power densities than the inactive EO pump (closed symbol) tests. The maximum measured power density, 17.8 mW/cm2, is comparable to the 16 mW/cm2 reported by Lu et al.2 for a DMFC of similar size at room temperature.

|

Figure 3. Polarization (a) and power density (b) curves for the integrated DMFC/EO pump system. The data shows that activation of EO pump significantly improves DMFC performance. The maximum measured power density, 17.8 mW/cm2, is comparable to the 16 mW/cm2 reported by Lu et al.2 for a DMFC of similar size at room temperature. |

References

1. C. R. Buie, Y. Banin, T. Chuyang, J. G. Santiago, F. B. Prinz and B. L. Pruitt, in IEEE MEMS, IEEE, Istanbul, Turkey, 2006, pp. 938-941.

2. G. Q. Lu and C. Y. Wang, J. Power Sources, 2005, 144, 141-145.

(a) (b)

(a) (b)