Because of the constant introduction of various rules limiting engine power,

Formula 1 --- the pinnacle of motor racing technology --- has become all about

aerodynamics. While wind tunnels remain the most important aerodynamic design tool,

Computational Fluid Dynamics (CFD) has emerged as a serious capability for gaining

insight into the behavior of configurations that are impractical in a wind tunnel.

CFD has also become the preferred if not exclusive tool for the detailed design of components

such as mirrors and front wing endplates.

It is now also accepted as a complementary design capability for minimum drag or maximum downforce.

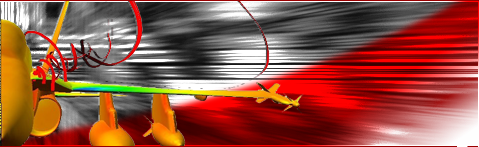

To obtain fairly accurate results, high-fidelity CFD models have to be built (more

than 26 millions nodes). This currently requires a few weeks to complete. This means

that during the off-season (3 to 4 months), the design engineers are capable of

building and testing a few car concepts which usually leads to misjudging the best

concept to use during the season (see fig. 1).

|

To this end, this project is focused on developing a set of numerical tools for the

preliminary aerodynamic design of the Formula 1 car based on advanced reduced-order

modeling (ROM) technologies. The objective is to obtain a reduction in computational

cost of at least one order of magnitude. This will allow the engineers to build and

test more concepts and eventually decide on the best one.

|